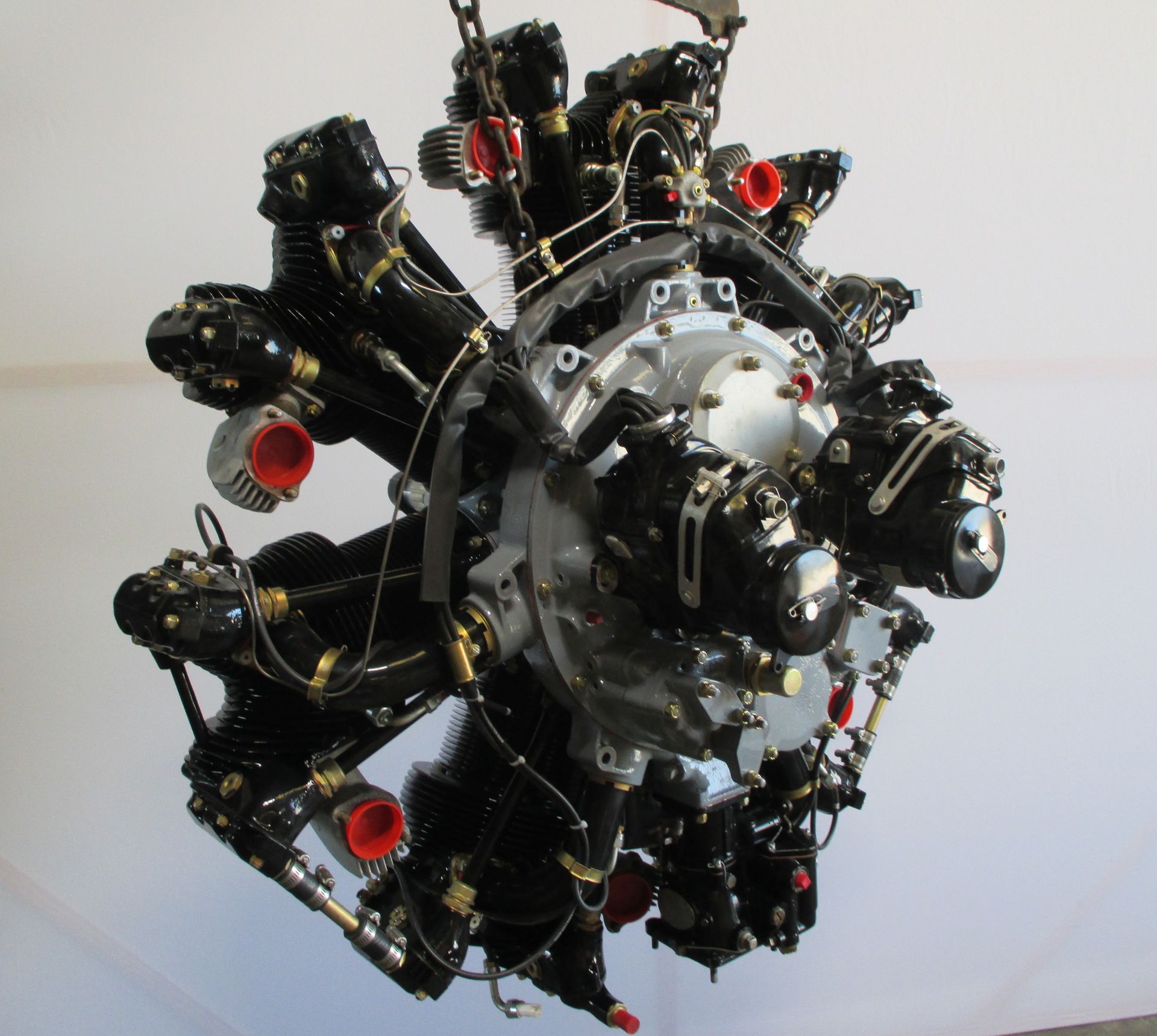

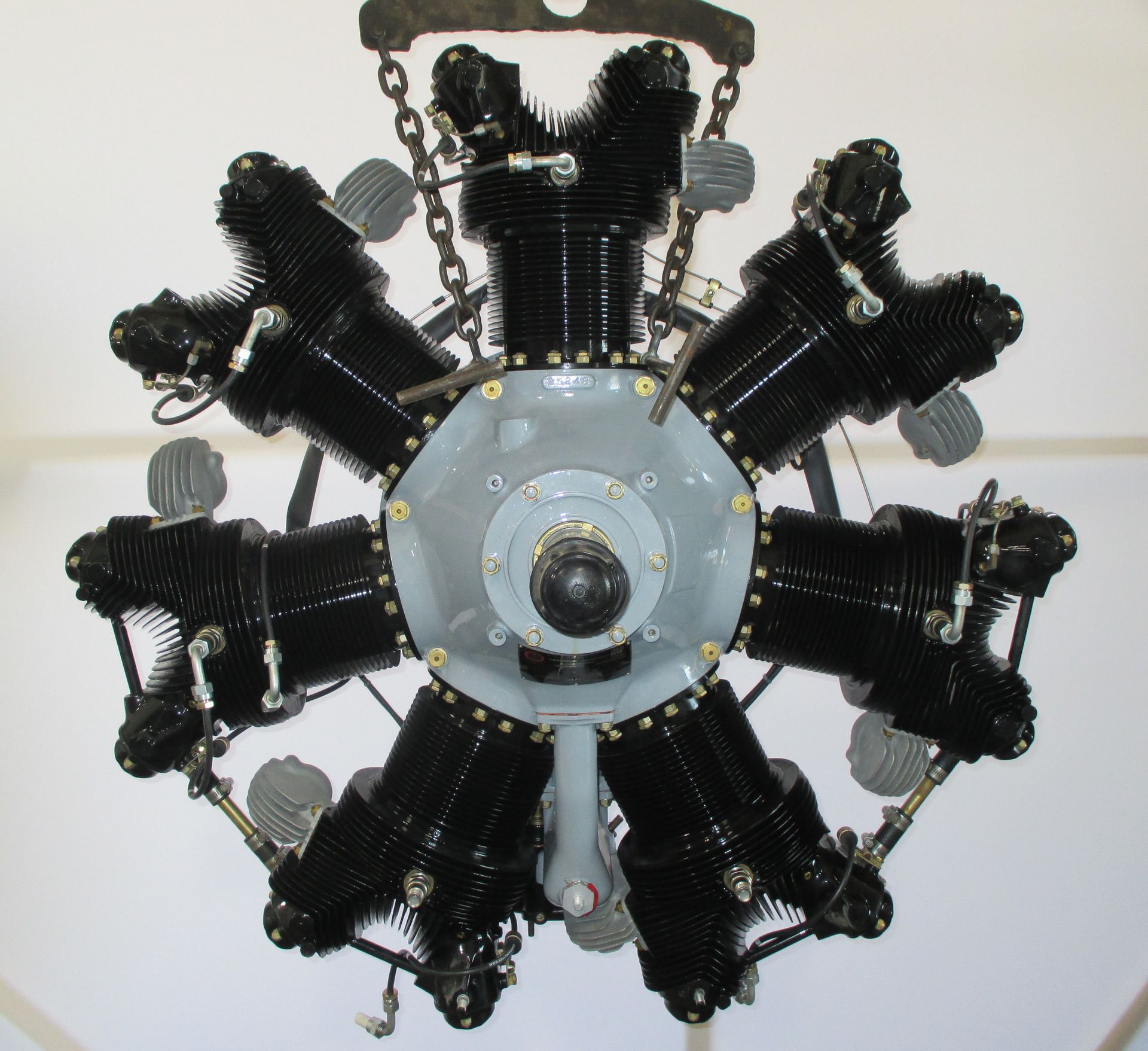

AIR REPAIR INC. W670 ENGINE INFORMATION

| W-670 | |

|---|---|

| Exchange | $39,950.00 |

| Core | $6,000.00 |

| Outright | $45,950.00 |

At Air Repair Inc., we specialize in the overhaul and repair of radial engines, and one engine that often comes through our shop is the W670. Known for its reliability and performance, the W670 has a rich history in aviation, powering countless aircraft with its robust design. Our team of skilled technicians takes pride in breathing new life into these iconic engines, ensuring they meet modern safety and performance standards. Whether your W670 needs a full overhaul or specific repairs, we treat each engine with the care it deserves, so you can get back in the air with confidence. Trust us to keep your aircraft soaring high!

What's in every Air Repair Engine?

FAA PMA Roller Main Bearings

FAA PMA data plate

FAA PMA tappet rollers

FAA PMA Master Rod Bearing

FAA PMA pistons

New Skytronics shielded ignition harness per ARI Proprietary Service Bulletin AR007

New Thrust Bearing

Nu-Chrome cylinders

New or replated hardware

New rings

Overhauled mags – either type

Overhauled carburetor

New roller pins

New tappets

New thrust nut

New slinger

New piston pins

New link rods

New intake and exhaust valves

New valve springs

New knuckle pins

New valve keepers

New rocker arm bearings

New rocker arm rollers

New 3915 starter gear

New 3064 oil pump gears

New 3062 intermediate gear

New gear pin mount

New step up pinion gear

New step up bearings

New duplex pump gears

New rocker scavenge pump

New primer lines

New oil screen

New Installation gasket set

New Exhaust nuts

Air Repair, Inc. Proprietary Service Bulletins:

AR003 Stainless Hose Clamps

AR005 #4 Intake Pipe Quick Drain

AR007 Skytronics Shielded Ignition Harness

AR008 New Crankcase Liners

AR009 Removable Intake Pipes

AR010 Crankpin Cleaning

AR011 Crankshaft Plating

AR012 Lower Cylinder Base Torque

AR013 UREM37BY Spark Plugs

AR014 Cam Regrinding

AR015 W670-6A, -6N Magneto

AR016 Modified Tachometer Housing, Improved Oil Sealing

AR017A W670 Piston/Ring Configurations & Fits

**Includes UREM37BY Spark Plugs**